Galvanized iron wire, soft annealed, electro galvanized and hot

dipped galvanised, pvc or epoxy coated into colors. Made of high carbon, medium and low carbon steel.

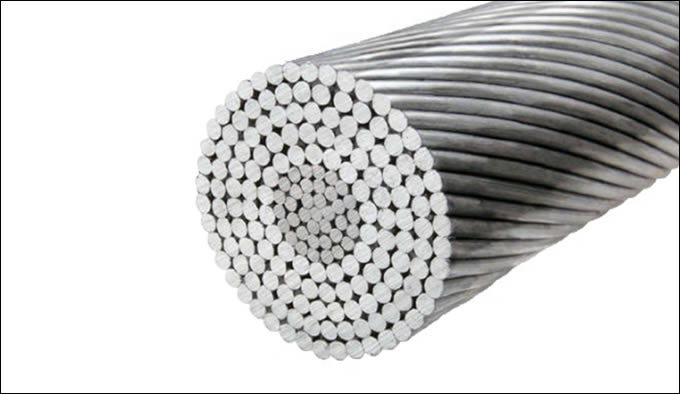

Everbright supplies quality Galvanized steel wires used as a reinforcing core for aluminum conductor steel reinforced ACSR conductors. ACSR conductors widely used as bare overhead transmission cable, are made with Aluminum alloy 1350-H-19 wires and stranded steel core wire. The core wire size and mechanical properties we supply are as standard quality specified in ASTM B 498 , IEC 60888 , BS EN 50189.

The steel core wire for the conductor is either single wire or stranded wire of 7 and 19 wires.

For corrsion protection, the ACSR core wire is hot dipped galvanized to A Grade galvanization, while B, C grade zinc coating also upon request. The galvanized steel core wire for ACSR conductor is greased with a purpose for increased anti-corrosion performance. The special grease applied can with stand a high temperature up to 180 ºC.

Number of steel wire used as ACSR core wire: The proportion of steel and aluminium wire in an ACSR conductor varies according to the mechanical strength requirements. We are listing below a list for references.

Packing:

The galvanized steel wire is supplied on wooden drums, with suitable drum dimension for the cutting length of the wire. Also, the drum dimension is approved before delivery by our customers to suit different machine uses.

Everbright uses treated wooden or strong plywood drums, which are strong enough to avoid damage during transportation, handling and storage.

Each drum is with a tag including the supplier name, purchasing order number, box number, wire size, net weight and gross weight.

Galvanized steel wire, stranded structure in 7X1.44MM, for ACSR, 70/12MM2

Standard for 7X1.44MM ACSR Wire: ASTM B 498, ASTM B 232

Inner wire need to be greased

Technical specifications: Wire Size, Weight, Grease Type and Tenisle Strength

| Individual wire diameter | mm | 1.44 |

| No. of wires | pcs | 7 |

| Cross-sectional area | mm2 | 12 |

| Overall diameter | mm | 4.32 |

| Total weight with grease | Kg/km | 90.6 (-0,+ 2%) |

| Cutting length | mt. | As per P.O |

| Type of grease | OCG5000 or Equivalent | |

| Lay ratio range Tensile strength of wire (before stranding) | Mpa | 16-26 1340 |

| Tensile strength of wire (after stranding) | Mpa | 1273 |

Wire Length, Wire Diameter Tolerance, Grease Weight and Zinc Coating Class

| Length | Wire No. | Wire Diameter | Lay Ratio | Extenal Lay Direction | Tolerance in wire diameter | Approx.weight of Grease | Min. mass of Zinc coating | ||

| M | mm | Min mm | Max mm | mm | mm | Kg/Km | Class A g / m2 | ||

| 4000 m (- 0,+3)% And Multipule of 4000 m | 7 | 1.44 | 16 | 26 | R.H | 0.03 | 0.03 | 1.8 | 195 |

Galvanized steel wire for ACSR, 40 MM2 (7X2.68 MM)

Galvanizing Standard for 7x2.68MM ACSR Wire: ASTM B 498 , ASTM B 232

Inner wire need to be greased

Technical specifications: Wire Size, Weight, Grease Type and Tenisle Strength

| Individual wire diameter | mm | 2.68 ± 0.04 |

| No. of wires | pcs | 7 |

| Cross-sectional area | mm2 | 40 |

| Overall diameter | mm | 8.04 |

| Total weight | Kg/km | 316± 2% |

| Cutting length | mt | 4000 +5% |

| Type of grease | OCG5000 or Equivalent |

Wire Length, Wire Diameter Tolerance, Lay Ratio, and Zinc Coating Class

| Length | Wire No. | Wire Diameter | Lay Ratio | External Lay Direction | Tolerance in wire diameter | Approx.weight of Grease | Min. mass of Zinc coating | ||

| M | mm | Min mm | Max mm | mm | mm | Kg/Km | Class A g / m2 | ||

| 4000+5% | 7 | 2.68 | 16 | 26 | R.H | 0.04 | 0.04 | 6.6 | 240 |

ACSR Conductor Wire Structures

The Proportion of Steel Wire and Aluminium Wire in an ACSR conductor results in various mechanical properties:

ACSR Conductor Wire Structures / Compositions and Property Reference Lists

| Nominal Section | Wire Numbers / Diameter | Area | Strand Wire Out Diameter | Unit Weight | Rated Tensile Strength kN | D.F. at 20 Centigrade | |||||

| Aluminum | Steel | Aluminum | Steel | Total | JLHA1 | ||||||

| No./mm | mm2 | mm | kg/km | G1A | G3A | EST | Ω/km | ||||

| 150/8 | 18/3.20 | 1/3.20 | 144.76 | 8.04 | 152.80 | 16.00 | 461 | 55.90 | 58.15 | 59.51 | 0.2311 |

| 150/20 | 24/2.78 | 7/1.85 | 145.68 | 18.82 | 164.50 | 16.67 | 549 | 69.36 | 74.63 | 76.51 | 0.2301 |

| 185/10 | 18/3.60 | 1/3.60 | 183.22 | 10.18 | 193.40 | 18.00 | 584 | 68.91 | 71.35 | 72.98 | 0.1826 |

| 185/25 | 24/3.15 | 7/2.10 | 187.04 | 24.25 | 211.29 | 18.90 | 706 | 89.15 | 95.94 | 98.37 | 0.1792 |

| 185/30 | 26/2.98 | 7/2.32 | 181.34 | 29.59 | 210.93 | 18.88 | 732 | 92.67 | 100.66 | 104.80 | 0.1850 |

| 210/10 | 18/3.80 | 1/3.80 | 204.14 | 11.34 | 215.48 | 19.00 | 650 | 76.78 | 79.50 | 81.32 | 0.1639 |

| 210/25 | 24/3.33 | 7/2.22 | 209.02 | 27.10 | 236.12 | 19.98 | 789 | 99.63 | 107.22 | 109.93 | 0.1604 |

| 210/35 | 26/3.22 | 7/2.50 | 211.73 | 34.36 | 246.09 | 20.38 | 853 | 107.98 | 117.26 | 122.07 | 0.1584 |

| 210/50 | 30/2.98 | 7/2.98 | 209.24 | 48.82 | 258.06 | 20.86 | 960 | 123.66 | 136.84 | 143.68 | 0.1603 |

| 240/30 | 24/3.60 | 7/2.40 | 244.29 | 31.67 | 275.96 | 21.60 | 922 | 113.05 | 121.60 | 126.04 | 0.1372 |

| 240/40 | 26/3.42 | 7/2.66 | 238.85 | 38.90 | 277.75 | 21.66 | 964 | 121.97 | 132.47 | 137.92 | 0.1405 |

| 240/55 | 30/3.20 | 7/3.20 | 241.27 | 56.30 | 297.57 | 22.40 | 1107 | 140.34 | 156.10 | 165.68 | 0.1392 |

| 300/15 | 42/3.00 | 7/1.67 | 296.88 | 15.33 | 312.21 | 23.01 | 940 | 114.43 | 118.72 | 120.25 | 0.1130 |

| 300/20 | 45/2.93 | 7/1.95 | 303.42 | 20.91 | 324.33 | 23.43 | 1001 | 123.07 | 128.92 | 131.01 | 0.1106 |

| 300/25 | 48/2.85 | 7/2.22 | 306.21 | 27.10 | 333.31 | 23.76 | 1058 | 131.22 | 138.81 | 141.52 | 0.1096 |

| 300/40 | 24/3.99 | 7/2.66 | 300.09 | 38.90 | 338.99 | 23.94 | 1132 | 138.87 | 149.38 | 154.82 | 0.1117 |

| 300/50 | 26/3.83 | 7/2.98 | 302.68 | 48.82 | 351.50 | 24.26 | 1210 | 150.01 | 163.20 | 170.03 | 0.1120 |

| 300/70 | 30/3.60 | 7/3.60 | 305.36 | 71.25 | 376.61 | 25.20 | 1401 | 174.57 | 191.67 | 203.07 | 0.1099 |

| 400/20 | 42/3.51 | 7/1.95 | 406.40 | 20.91 | 427.31 | 26.90 | 1286 | 152.48 | 158.33 | 160.42 | 0.0825 |

| 400/25 | 45/3.33 | 7/2.22 | 391.91 | 27.10 | 419.01 | 26.60 | 1294 | 159.07 | 166.66 | 169.37 | 0.0856 |

| 400/35 | 48/3.22 | 7/2.50 | 390.88 | 34.36 | 425.24 | 26.80 | 1348 | 166.21 | 175.49 | 180.30 | 0.0859 |

| 400/50 | 54/3.07 | 7/3.07 | 399.73 | 51.82 | 451.55 | 27.60 | 1510 | 186.91 | 201.42 | 210.23 | 0.0840 |

| 400/65 | 26/4.42 | 7/3.44 | 398.94 | 65.06 | 464.00 | 28.00 | 1610 | 197.23 | 215.45 | 226.51 | 0.0841 |

| 400/95 | 30/4.16 | 19/2.50 | 407.75 | 93.27 | 501.02 | 29.10 | 1858 | 234.77 | 259.95 | 273.01 | 0.0823 |

| 500/35 | 45/3.75 | 7/2.50 | 497.01 | 34.36 | 531.37 | 30.00 | 1641 | 195.73 | 205.01 | 209.82 | 0.0675 |

| 500/45 | 48/3.60 | 7/2.80 | 488.58 | 43.10 | 531.68 | 30.00 | 1687 | 203.04 | 214.68 | 220.71 | 0.0687 |

| 500/65 | 54/3.44 | 7/3.44 | 501.88 | 65.06 | 566.94 | 31.00 | 1896 | 234.68 | 252.89 | 263.95 | 0.0669 |

| 630/45 | 45/4.22 | 7/2.81 | 629.40 | 43.10 | 672.50 | 33.75 | 2078 | 247.70 | 259.50 | 265.55 | 0.0533 |

| 630/55 | 48/4.12 | 7/3.20 | 639.92 | 56.30 | 696.22 | 34.30 | 2208 | 263.50 | 279.27 | 288.84 | 0.0525 |

| 630/80 | 54/3.87 | 19/2.32 | 635.19 | 80.32 | 715.51 | 34.80 | 2386 | 291.65 | 313.34 | 324.58 | 0.0529 |

| 800/55 | 45/4.80 | 7/3.20 | 814.30 | 56.30 | 870.60 | 38.40 | 2689 | 318.43 | 334.20 | 343.77 | 0.0412 |

| 800/70 | 48/4.63 | 7/3.60 | 808.15 | 71.25 | 879.40 | 38.60 | 2790 | 332.95 | 350.05 | 361.45 | 0.0415 |

| 800/100 | 54/4.33 | 19/2.60 | 795.17 | 100.90 | 896.07 | 39.00 | 2989 | 365.48 | 392.72 | 406.84 | 0.0422 |

Consult Everbright for more detailed technical information.

- Galvanized Iron Wire

- ASTM A 641 Galvanized Wire Standard

- Cold Heading Wire

- Brass Coated Wire

- Hot Dip Galvanized Wire ASTM A-475

- Trellis Wire

- High Carbon Galvanized Steel Wire

- Nose Wire

- Phosphate Coated Steel Wire

- Spiral Binding Wire

- Champagne Cork Wire

- PC Strand

- Chain Link Security Fence

- Galvanized Welded Wire Mesh

- Galvanized Hexagonal Wire Mesh

- Galvanized Wire Mesh Fence

- Galvanized Core Wire for ACSR

- Galvanized Steel Stranded Core Wire

- Galvanized Wire (GI Wire)

- Oil Tempered Steel Wire

- Electro Galvanized Iron Wire

- Hot Dipped Zinc Plated Wire

- Spring Steel Wire

- High Carbon Spring Steel Wire

- Technical Details of Hot Dip Galvanized Wire

- Galvanized Steel Wire

- Copper Coated Steel Wire

- Hot Galvanized Wire Products for Portugal Market

- Oval Wire

- Fencing Wire

- Mild Steel Wire

- Low Carbon Steel Wire

- Redrawing Wire

- Annealed Wire

- Black Iron Wire

- Binding Wire

- Wire Ties

- Loop Tie Wire

- Rebar Tie Wire

- Cut Wire

- Stitching Wire

- Armoured Cable Wire

- Welding Wire

- PVC Coated Wire

- PVC Coated Steel Wire Technical Parameter

- Coil Wire

- Spool Wire

- Barbed Wire

- Baling Wire

- Staple Wire

- Hose Wire

- Music Wire

- Brush Wire (Wire for Brushes)

- High Tensile Wire

- Razor Wire

- Galvanized Wire for Armouring Cable

- Galfan Wire

- Galvanized Wire Mesh

- Galvanized Flat Stitching Wire

- Lashing Wire

- Galvanized Wire Rope