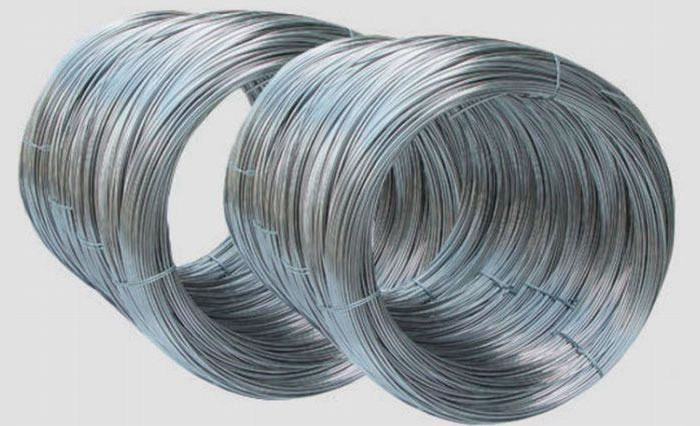

Galvanized iron wire, soft annealed, electro galvanized and hot

dipped galvanised, pvc or epoxy coated into colors. Made of high carbon, medium and low carbon steel.

Hot Dipped Galvanized Steel Wire - Zinc Coated Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

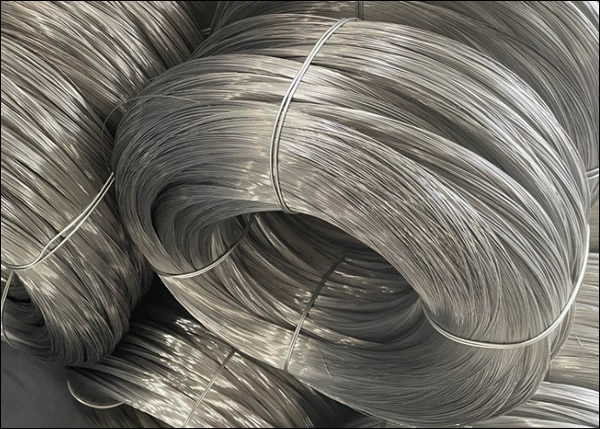

General Introduction: Hot-dipped zinc plated wire is also known as hot dipped galvanized wire or thermal galvanized wire. It is made by mean of wire drawing followed by heat treatment and melt zinc plating.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spanish Standard Heavily Galvanized Wire (Hot dipped Galvanized Materials) for different applications

Hot Dipped Galvanized High Carbon Steel Wire for ACSR (Aluminum Conductor Steel Reinforced) Cables - Ø 2.68mm PRODUCT: High carbon steel wire with hot dip galvanizing, mainly used as reinforcing cable wire for verhead transmission and distribution conductors. In the form of wire rod. The full specification as following: Galvanizing steel wire ( before stranding ):

High Carbon Steel Wire BTC Galvanized for Fences - Ø 2,76 mm.

Wire material for manufacture of razor barbed wire and fences: Galvanized wire, high carbon steel, diameter 2,76mm and minimum 50g/square meter zinc rate The detailed specification as following: PRODUCT: WIRE BTC GALVANIZED FOR FENCES - Ø 2,76 mm. Manufactured as per standard NBR 6331/2010, tensile strengh quality "macia/soft" and "leve/light" zinc layer. Main Carachteristics for the WIRE BTC GALVANIZED (BWG 12)

Concertina barbed wire, hot dip galvanized

Type hot dip galvanized, Gabion wire

Material: Hot dip galvanized Wire (>260g/ m2) Hot-Dip Galvanized Steel Wire for New PVC DIN250 Spools (20kg/spool) 0.20mm Diameter (±0.005mm Tolerance) Bright electro galvanized wire and hot-dipped galvanizes wires base on Malaysian Standard MS 1137 on minimum zinc coating. The packing for wire sizes 0.90-1.25mm is pattern lay 250-300kgs, ID/OD as standard production; for wire 1.60mm-4.00mm is pattern lay 500kgs+-. ID/OD standard production. Zinc-coated Thin wire Soft Hot Dipped Galvanized wire BWG 8 Hot Dipped Galvanised Wire for Italy in 600kg and 25kg coils: 1)Hot dipped galvanized wire in rosette coils kg 600 2)Hot dipped galvanized wire in coils of 25 kg

High Carbon Tensile Wire, Hot Dipped Galvanised

Hot Dip Galvanized Wire in Various Packing Forms

Why Choose Galvanized Steel Wire Thermal Zinc Plated? Or, the major Differences between Thermal galvanized and electro galvanized wire? Galvanized wire hot-dip zinc-plated is also known as thermal zinc plated gal. wire or HDG wire. Electro-galvanized wire is also called electroplating wire or cold galvanized wire. They are all produced from quality wire rods of 1006、1008、1018、Q195. The zinc applied for plating is ZINC WITH 99.995% purity. Hot dip galvanized wire and electro galvanized steel wire both can be used extensively as weaving wire, tying wire, staple wire and fencing wire. Similar wire diameters applied to them.

The major differences lies in three aspects: the zinc coating processing method, the zinc coating quantity and the wire properties. Processing Differences: Thermal zinc plating or hot dip plating is made by placing the steel wire immersed in a liquid bath of hot melt zinc. The zinc layer is formed through intense high-temperature chemical reaction process. Hence, the electroplating is also called cold plating and the later hot dip plating. Zinc layer thickness and zinc coating quantity difference: Zinc Coating for Cold Galvanized Steel Wire:

Zinc Coating for Hot Dipped Zinc Plating Wire:

Property and Service Life Differences: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Galvanized Iron Wire

- ASTM A 641 Galvanized Wire Standard

- Cold Heading Wire

- Brass Coated Wire

- Hot Dip Galvanized Wire ASTM A-475

- Trellis Wire

- High Carbon Galvanized Steel Wire

- Nose Wire

- Phosphate Coated Steel Wire

- Spiral Binding Wire

- Champagne Cork Wire

- PC Strand

- Chain Link Security Fence

- Galvanized Welded Wire Mesh

- Galvanized Hexagonal Wire Mesh

- Galvanized Wire Mesh Fence

- Galvanized Core Wire for ACSR

- Galvanized Steel Stranded Core Wire

- Galvanized Wire (GI Wire)

- Oil Tempered Steel Wire

- Electro Galvanized Iron Wire

- Hot Dipped Zinc Plated Wire

- Spring Steel Wire

- High Carbon Spring Steel Wire

- Technical Details of Hot Dip Galvanized Wire

- Galvanized Steel Wire

- Copper Coated Steel Wire

- Hot Galvanized Wire Products for Portugal Market

- Oval Wire

- Fencing Wire

- Mild Steel Wire

- Low Carbon Steel Wire

- Redrawing Wire

- Annealed Wire

- Black Iron Wire

- Binding Wire

- Wire Ties

- Loop Tie Wire

- Rebar Tie Wire

- Cut Wire

- Stitching Wire

- Armoured Cable Wire

- Welding Wire

- PVC Coated Wire

- PVC Coated Steel Wire Technical Parameter

- Coil Wire

- Spool Wire

- Barbed Wire

- Baling Wire

- Staple Wire

- Hose Wire

- Music Wire

- Brush Wire (Wire for Brushes)

- High Tensile Wire

- Razor Wire

- Galvanized Wire for Armouring Cable

- Galfan Wire

- Galvanized Wire Mesh

- Galvanized Flat Stitching Wire

- Lashing Wire

- Galvanized Wire Rope