Galvanized iron wire, soft annealed, electro galvanized and hot

dipped galvanised, pvc or epoxy coated into colors. Made of high carbon, medium and low carbon steel.

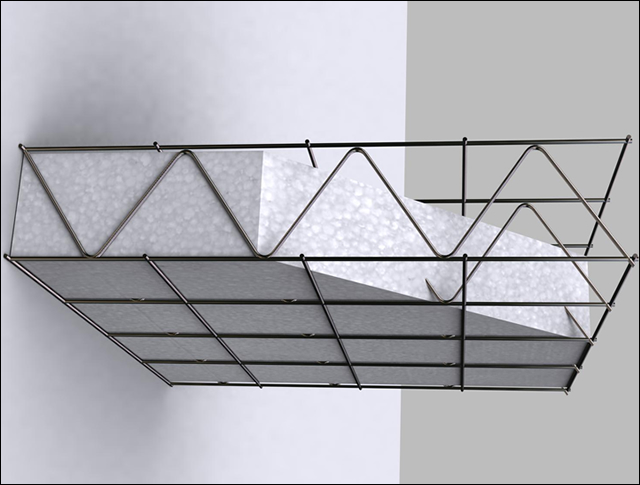

3D Wire Block Panel for Wall and Roof Construction Building System

3D Panels are building materials made with a three-dimensional (3D) wire structure, commonly filled with Expanded Polystyrene (EPS). Mainly used in the construction and architectural fields for walls, roofs, and floors, these multifunctional panels provide excellent insulation and versatile building solutions.

Expanded Polystyrene (EPS) 3D Panels

EPS 3D panels are a composite construction material, combining EPS with a three-dimensional wire framework. EPS, derived from Expandable Polystyrene, is a rigid foam with an expansion agent that forms air-trapping bubbles, making it an excellent insulator. The wire panels filled EPS are lightweight, strong, and thermally resistant, ideal in construction for insulating walls, roofs, and floors. EPS 3D Panels are often simplified as 3D Panels in constructional uses.

Structure - Galvanized Wire and Foamed Polystyrene Insulating

EPS 3D panels consists of galvanized wire mesh and foamed polystyrene: The core of the panel is made of EPS, surrounded or embedded with a 3D wire mesh of galvanized steel, providing structural strength and rigidity.

Galvanized wire provides a strong, rust-resistant framework, while foamed polystyrene insulating core grants thermal and acoustic insulation.

Features

The design of 3D panels combination offers several unique properties:

Insulation: Excellent thermal insulation enhances energy efficiency.

Strength: Structural stability allows the panels to bear significant loads.

Versatility: Suitable for walls, roofs, floors, packaging, and other lightweight insulation applications.

Lightweight: Facilitates easy handling and installation.

Cost-Effective: A more affordable alternative to traditional construction materials.

Environmentally friendly.

Easy to install.

Why Using EPS 3D Panels for Works in Construction

EPS 3D panels are widely used in residential and commercial buildings where energy efficiency and rapid construction are needed, for following reasons:

1, The EPS 3D panels maintain sustainable and cost-effective structures, from large commercial buildings to low-cost housing.

2, Innovations and custom specifications can be supplied such as 50mm thick EPS 3D panels to meet specific project requirements.

3, A variety of combination of wire frame work and EPS fillings is available for construction options.

4.

3D panels offer a promising and resilient alternative to traditional building methods.

3D Panel Specifications Terms - How to Describe 3D Panel Products

- Hole Size

The hole size in 3D wire mesh block panels varies to accommodate different construction needs, typically ranging from 50mm to 100mm.

- Thickness of 3D Panel

3D panels usually come in thicknesses ranging from 50mm to 150mm.

- Weight

The weight of a 3D panel depends on its size and materials but is generally lighter compared to traditional construction materials.

- Length

Lengths vary and can be customized according to the project requirements.

- Polystyrene Thickness

Thick polystyrene within 3D panels is used to ensure adequate thermal insulation.

- Expanded Polystyrene Core

Expanded Polystyrene (EPS) provides a lightweight yet rigid core, with thicknesses like 50mm thick EPS 3D panels commonly used.

- 3D EPS Panel, Wall Panels, Roof Panels Thickness and Sizes

These specifications are tailored to the specific needs of the construction, with variations in thickness, panel size, and type to suit different applications.

Types

3D panels can be classified into:

3D Wire Mesh Block Panels

3D EPS Panels

50mm Thick EPS 3D Panels

3D Panel for Wall Construction

Uses - 3D Panels for Construction

1, Used in commercial and residential buildings for walls, roofs, and floors.

2, 3D Wire Panel System for Construction of Low-Cost Housing

Package, Transport

3D panels are typically packaged in flat stacks, secured, and transported via trucks. Their lightweight nature makes them easy to handle and transport.

Installation

Installation of 3D panels is quick and requires minimal labor. It usually involves aligning the panels, connecting them with wire mesh, and then filling with concrete if needed.

3d EPS Wire Mesh Panels - Building Material Products Supplied for Projects Worldwide

3d eps wire mesh panels for India market

Specifications

Material: 2.5mm Galvanized Wire and foamed polystyrene insulating.

Hole size: 50mm×50mm

Thickness of 3D Panel: 90mm

3d panels for wall consruction in Sri lanka

3D Wire Panel system for construction of low cost housing

Panels specification

PANEL SPECIFICATION:

50 mm thick polystyrene

LENGTH 2.4mtr

WIDTH 1.2mtr

THICKNESS 75mm +/- 2mm

WIRE SPECIFICATION

WIRE (Electric galvanized low carbon wire, through secondary cold pull ) 2mm dia

CROSS WIRE(INSERTED WIRE) 2.5mm dia

Insertion of wire: 100mm.

Option size:

PANEL SPECIFICATION:

100mm thick polystyrene

LENGTH 2.4m

WIDTH 1.2 m

THICKNESS 114mm +/- 2mm

WIRE SPECIFICATION:

WIRE (Electric galvanized low carbon wire, through secondary cold pull ) 2mm dia

CROSS WIRE(INSERTED WIRE) 2.5mm dia

Insertion of wire 100mm.

3D Panel for Afghanistan Building Project

Panel size:

9m X 54m

9m X 27m

Panels have:

76 mm expanded polystyrene core.

The polystyrene core shall have a welded wire fabric of 50mm X 50mm mesh and 2.52 mm wire attached to both faces of the polystyrene core.

The welded wire mesh on each face shall be attached to each other and the polystyrene core with diagonal truss wires.

Apply sprayed concrete to a minimum thickness of 45 mm.

3D panel projects for Wall and Roof

We are provider of complete 3D panel project solutions, for architects, construction and building house project services.

3-D panels for building construction systems for 3D projects in Middle East / Afghanistan, South Africa, etc.

3d wire mesh block panel for Croatia- Europa.

3D panel eps for Karachi port of Pakistan:

Wall panels 120mm thick total 1,700 sqm

Roof panel total 1,700 sqm

- Galvanized Iron Wire

- ASTM A 641 Galvanized Wire Standard

- Cold Heading Wire

- Brass Coated Wire

- Hot Dip Galvanized Wire ASTM A-475

- Trellis Wire

- High Carbon Galvanized Steel Wire

- Nose Wire

- Phosphate Coated Steel Wire

- Spiral Binding Wire

- Champagne Cork Wire

- PC Strand

- Chain Link Security Fence

- Galvanized Welded Wire Mesh

- Galvanized Hexagonal Wire Mesh

- Galvanized Wire Mesh Fence

- Galvanized Core Wire for ACSR

- Galvanized Steel Stranded Core Wire

- Galvanized Wire (GI Wire)

- Oil Tempered Steel Wire

- Electro Galvanized Iron Wire

- Hot Dipped Zinc Plated Wire

- Spring Steel Wire

- High Carbon Spring Steel Wire

- Technical Details of Hot Dip Galvanized Wire

- Galvanized Steel Wire

- Copper Coated Steel Wire

- Hot Galvanized Wire Products for Portugal Market

- Oval Wire

- Fencing Wire

- Mild Steel Wire

- Low Carbon Steel Wire

- Redrawing Wire

- Annealed Wire

- Black Iron Wire

- Binding Wire

- Wire Ties

- Loop Tie Wire

- Rebar Tie Wire

- Cut Wire

- Stitching Wire

- Armoured Cable Wire

- Welding Wire

- PVC Coated Wire

- PVC Coated Steel Wire Technical Parameter

- Coil Wire

- Spool Wire

- Barbed Wire

- Baling Wire

- Staple Wire

- Hose Wire

- Music Wire

- Brush Wire (Wire for Brushes)

- High Tensile Wire

- Razor Wire

- Galvanized Wire for Armouring Cable

- Galfan Wire

- Galvanized Wire Mesh

- Galvanized Flat Stitching Wire

- Lashing Wire

- Galvanized Wire Rope