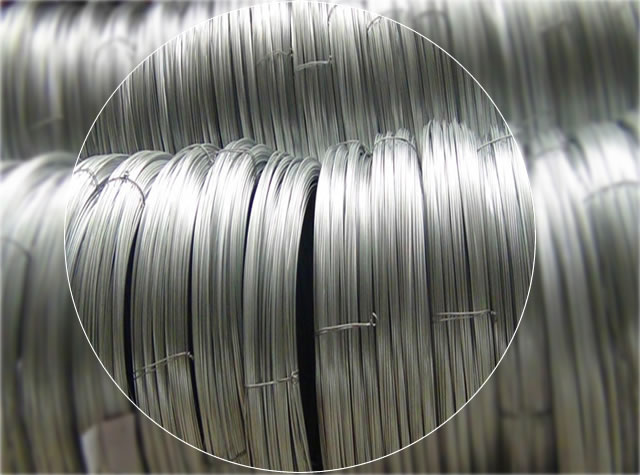

Galvanized iron wire, soft annealed, electro galvanized and hot

dipped galvanised, pvc or epoxy coated into colors. Made of high carbon, medium and low carbon steel.

Galvanized Steel Stranded Core Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

We are exporter and supplier of good quality Galvanized Steel Wire Strands, known as Core Wires for cables and various industrial uses. We have: Structures: 1*3/1*7/1*19/1*37 Main Types: OPGW Galvanized Steel Ground Wire

Material: Zinc coated galv. steel wire for optical ground wire ( OPGW ) coring. Zinc coating mass requirements

Mechanical properties,torsion twist requirements and wrap test mandrel diameter for extra high strength steel wires

Initial stress and extensometer setting for determination of stress 1% extension

Hot Dip Galvanized Steel Wire For ACSR Coring

Material: Hot Dipped Steel Stranded Wire Specification:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Galvanized Iron Wire

- ASTM A 641 Galvanized Wire Standard

- Cold Heading Wire

- Brass Coated Wire

- Hot Dip Galvanized Wire ASTM A-475

- Trellis Wire

- High Carbon Galvanized Steel Wire

- Nose Wire

- Phosphate Coated Steel Wire

- Spiral Binding Wire

- Champagne Cork Wire

- PC Strand

- Chain Link Security Fence

- Galvanized Welded Wire Mesh

- Galvanized Hexagonal Wire Mesh

- Galvanized Wire Mesh Fence

- Galvanized Core Wire for ACSR

- Galvanized Steel Stranded Core Wire

- Galvanized Wire (GI Wire)

- Oil Tempered Steel Wire

- Electro Galvanized Iron Wire

- Hot Dipped Zinc Plated Wire

- Spring Steel Wire

- High Carbon Spring Steel Wire

- Technical Details of Hot Dip Galvanized Wire

- Galvanized Steel Wire

- Copper Coated Steel Wire

- Hot Galvanized Wire Products for Portugal Market

- Oval Wire

- Fencing Wire

- Mild Steel Wire

- Low Carbon Steel Wire

- Redrawing Wire

- Annealed Wire

- Black Iron Wire

- Binding Wire

- Wire Ties

- Loop Tie Wire

- Rebar Tie Wire

- Cut Wire

- Stitching Wire

- Armoured Cable Wire

- Welding Wire

- PVC Coated Wire

- PVC Coated Steel Wire Technical Parameter

- Coil Wire

- Spool Wire

- Barbed Wire

- Baling Wire

- Staple Wire

- Hose Wire

- Music Wire

- Brush Wire (Wire for Brushes)

- High Tensile Wire

- Razor Wire

- Galvanized Wire for Armouring Cable

- Galfan Wire

- Galvanized Wire Mesh

- Galvanized Flat Stitching Wire

- Lashing Wire

- Galvanized Wire Rope